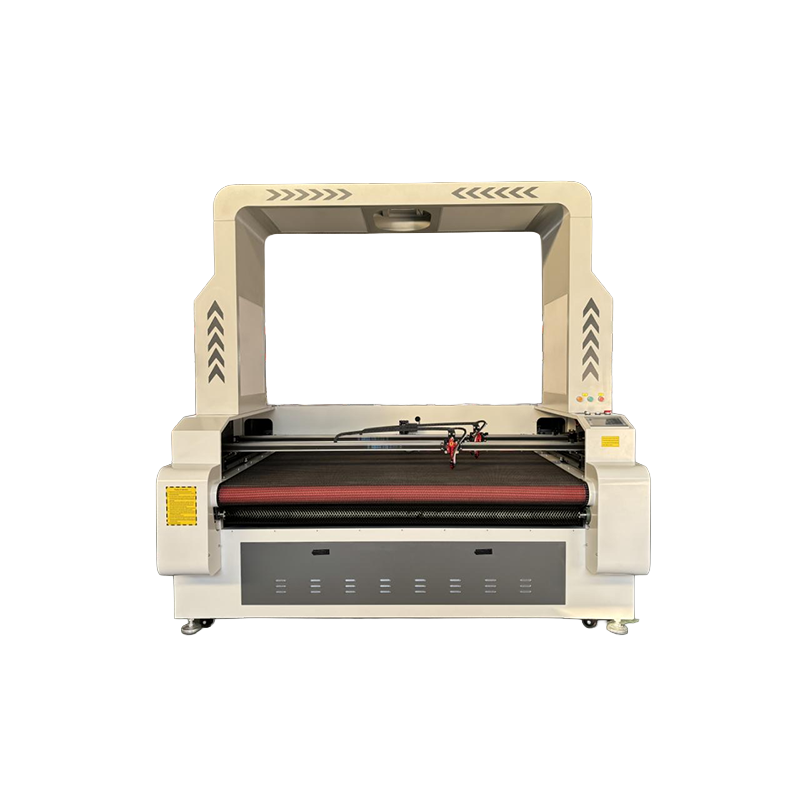

4040 CO2 Laser Engraving Machine

|

Specifications |

|

| Laser Power | 40W 50W |

| Laser Type | Hermetic co2 glass tube |

| Power Supply | AC220±10% 50HZ/AC 110±10% 60HZ |

| Working Area | 400mm*400mm |

| Max Moving Speed | 0---500mm/s |

| Up&Down worktable | Electric up-down worktable |

| Worktable | Honeycomb Worktable/Aluminium Knife(optional) |

| Locating Precision | <0.01mm |

| Min Shaping Character | Character:3*3mm, letter:2*2mm |

| Operating Temperature | 5℃---35℃ |

| Resolution Ratio | ≤2500dpi |

| Control Configuration | DSP |

| DataTransfer Interface | USB(offline) |

| Svstem Environment | WINDOWS 2000/WINDOWS XP/Vista/win7/win8/win10 |

| Cooling Way | water cooling and protection system |

| Graphic Format Supported | The files which CoreDraw,photoshop,AutoCAD can identify(BMP,GIF,JPEG,PCX,TGA,TIFF,PLT,CDR,DMG,DXF,PAT,CDT,CLK,DEX,

CSL,CMX,AI,WPG,WMF,EMF,CGM,SVG,SVGZ,PCT,FMV,GEM,CMX) |

| Compatible software | the files which CoreDraw,photoshop,AutoCAD can identify(BMP,GIF,JPEG,PCX,TGA,TIFF,PLT,CDR,DMG,DXF,PAT,CDT,CLK,DEX,

CSL,CMX,AI,WPG,WMF,EMF,CGM,SVG,SVGZ,PCT,FMV,GEM,CMX) |

| Cutting Thickness | 0---20mm(Depends on different materials) |

| Color Separation | separation of cutting up to 256 colors |

| Sloping Engraving | yes,slope can be designed discretionarily |

| Cuts off the Water Supply the Protection | yes |

| Machine Dimension | 900*740*420mm |

| Package Dimension | 1000*850*660cmmm |

| New Weight | 50KG |

| Gross Weight | 80kg |

Product Description:

When it comes to material adaptability, CO2 laser engravers excel. It is capable of engraving a variety of materials, including wood, acrylic, fabric, leather, paper, plastic, glass, ceramics, and more. Whether it is soft fabric or hard glass, it can present exquisite engraving effects under its action, which makes it extremely practical in industries such as handicraft production, advertising signage, packaging and printing.

High engraving accuracy is a distinctive feature of CO2 laser engraving machines. Its laser beam focuses on a very small spot, enabling precise engraving of fine lines and complex patterns, with a minimum line width of up to the micron level. This is an indispensable advantage for products that require extremely high details, such as the logo of precision instruments, the pattern of jewelry, etc., and can effectively improve the quality and added value of the product.

In terms of efficiency, CO2 laser engraving machines are also quite competitive. Its engraving speed is fast, and it can complete a large number of processing tasks in a short period of time, and the processing process is continuous and stable, reducing the time of manual intervention. Compared with the traditional mechanical engraving method, it greatly shortens the production cycle, improves production efficiency, and is suitable for the needs of mass production.

Ease of operation and maintenance is also a highlight. The equipment is usually equipped with a user-friendly interface and automated control system, allowing operators to get started quickly with simple training, reducing the requirements for operator skill levels. At the same time, its structure is relatively simple, with few moving parts, low wear, and daily maintenance is mainly simple work such as regular cleaning of optical components, reducing maintenance costs and downtime.

In addition, CO2 laser engraving machines also have the advantage of environmentally friendly processing processes. There will be no large amount of dust and noise pollution during the engraving process, and there is no need to use auxiliary materials such as cutting fluid, which is conducive to maintaining a clean working environment and is in line with the concept of modern green production.

In summary, CO2 laser engraving machines have become important equipment in the field of modern processing with their wide material adaptability, high precision, high efficiency, easy operation and maintenance, and environmental protection, providing strong support for the development of various industries.