CCD Visual Positioning Laser Marking Machine: A High-Precision Solution for IC Engraving!

In the field of integrated circuit (IC) manufacturing, achieving precise and clear engraving on the tiny surfaces of chips has always been a focal concern in the industry. As chips become ever smaller and more integrated, traditional marking technologies have struggled to meet the stringent precision and efficiency demands of modern electronics manufacturing.

The emergence of CCD visual positioning laser marking technology, which equips laser devices with 'eyes' and a 'brain,' has completely addressed the positioning challenges in IC engraving, becoming one of the key technologies in today's semiconductor back-end packaging process.

1. Limitations of Traditional IC Marking Technology

As the core of electronic devices, IC chips handle processing and storage functions. Their surfaces need to be marked with clear patterns, numbers, and text for identification, traceability, and quality control. Traditional IC marking methods mainly use ink printing. With the continuous expansion of the market and increasing competition, users have higher requirements for IC strip markings, and traditional printing methods can no longer meet these demands.

Traditional processing methods have many limitations: there is considerable deviation in the marking position, low product quality, and low efficiency. Methods like sanding with sandpaper or grinding wheels to remove existing markings are inefficient, have a high rate of chip damage and scrap, and leave grinding marks on the surface, resulting in poor clarity of the new markings. For small surface-mount chips, manual operations are even more difficult. These issues severely restrict the development of the IC processing industry.

2. CCD Visual Positioning Laser Marking Technology Solution

#1. Technical Principle and System Composition

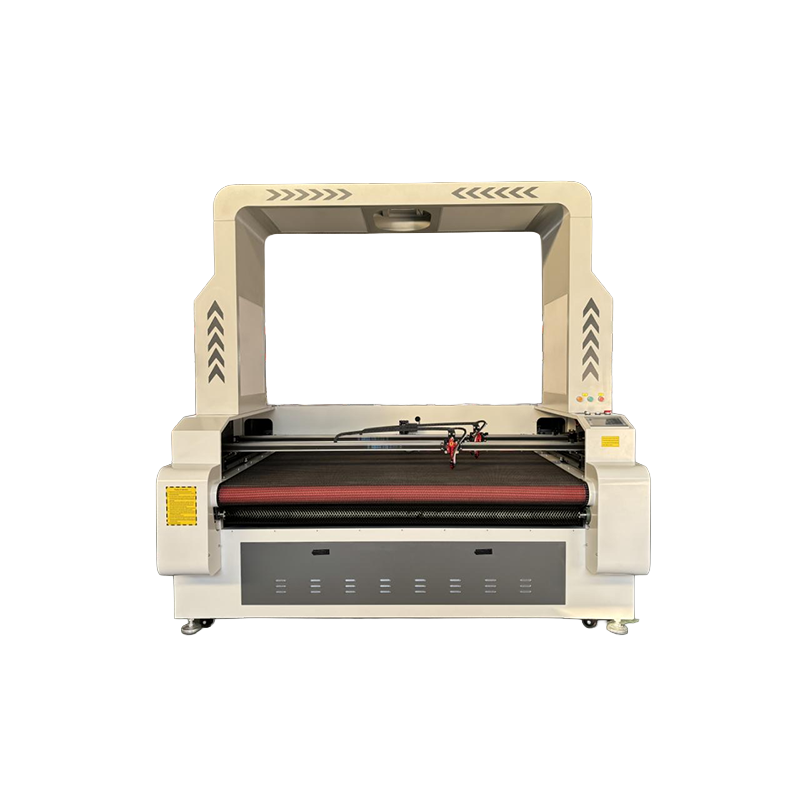

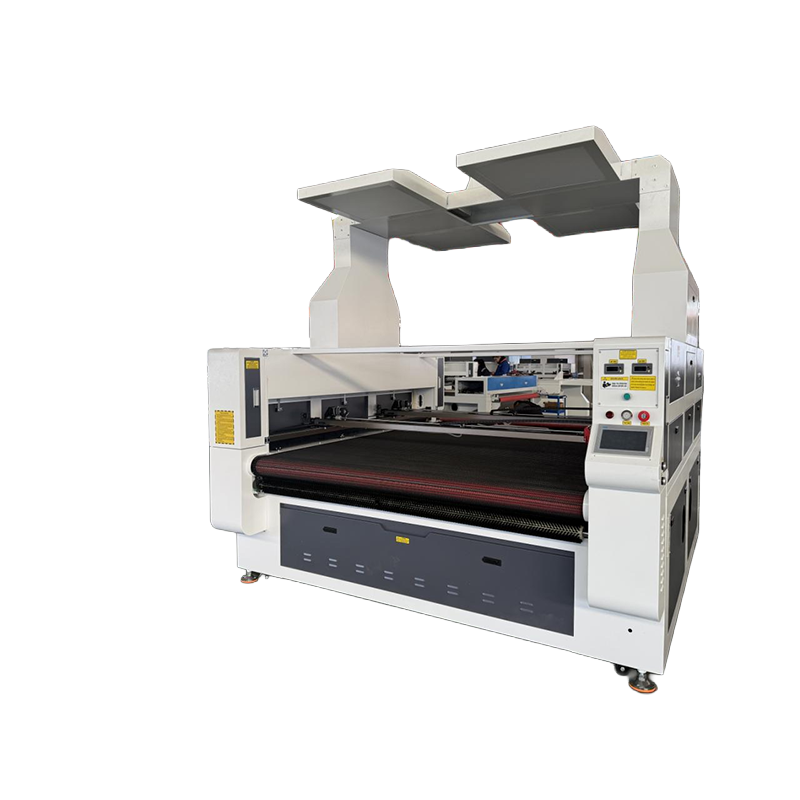

The CCD visual positioning laser marking machine integrates modern laser technology, computer vision, electrical control, and mechanical automation, covering multiple disciplines of opto-mechatronics. The system hardware mainly consists of hardware trigger devices, optical systems, cameras, acquisition cards, industrial computers, and marking equipment. Its core workflow includes:

- Image Acquisition: When a workpiece enters the camera's collection area, a trigger signal controls the camera to capture images.

- Image Processing: The software system performs calibration, positioning, and other data analysis on the captured images.

- Coordinate Transformation: The calculated pixel coordinates are converted into the physical coordinates of the laser.

- Precise Marking: The marking equipment completes the workpiece marking operation based on the received position information.

In terms of technical implementation, the system uses a pseudo-coaxial structure, where a beam splitter prism refracts the laser emitted from the side by 90° to direct it vertically downward. The CCD captures the IC product from above through the beam splitter prism for image analysis and positioning. The camera converts the calculated pixel coordinates into the laser's physical coordinates, controlling the laser galvanometer to deflect and achieve precise positioning and marking.

#2. Key Performance Indicators

The CCD vision positioning laser marking system demonstrates outstanding performance:

- Positioning Accuracy: Depending on different configurations, the marking accuracy can be controlled within 0.01-0.1mm.

- Processing Speed: With a camera frame rate of 60fps, the system processing cycle can be maintained at around 50ms.

- Communication Efficiency: The real-time communication between the system, hardware trigger devices, and marking equipment is generally controlled within 2ms.

- Production Capacity: Depending on the IC size, 10-12 ICs can be marked at a time, with a cycle time of approximately 30-35s, achieving a capacity of 80-100K/h.

3. Technical Advantages and Innovative Value

Compared with traditional technology, the CCD vision positioning laser marking machine offers multiple advantages:

1. High Precision and High Adaptability:

Using a CCD vision positioning system to guide the laser for marking ensures extremely precise positioning. The products to be processed can be placed arbitrarily, and multiple products can be placed at once. The software can automatically recognize products in any position, angle, or shape. Small-sized products are no longer a challenge for laser marking; the integration of vision technology makes the "small" become "large".

2. Simplified production process:

The precision of fixtures is no longer the determining factor for marking accuracy. Precise visual positioning frees the need for highly precise fixtures, making marking accuracy independent of the fixture. This not only reduces the cost of fixture production but also minimizes accuracy deviations caused by fixture wear.

3. Improved production efficiency:

CCD visual positioning laser marking machines can handle materials freely, achieving efficient marking and significantly enhancing marking productivity. The dual-head marking machine design allows two laser marking heads to work without interference while marking chips on the conveyor system, keeping the laser marker in constant operation, further increasing the production efficiency of chip marking.

4. Cost reduction and automation:

Fully automatic CCD visual positioning laser marking can be directly integrated with production lines, reducing production switching steps and manual handling, and can operate continuously 24/7 to meet the requirements of large-scale industrial online production. At the same time, laser marking is non-toxic, pollution-free, and highly efficient, meeting the demands of modern automated production and environmental protection.

Post time: 12-19-2025