Chuangxin Pioneers Vertical Integration, Strengthening the Foundation of China's Laser Core

According to the "2025 China Laser Industry Development Report," in 2024, China's laser equipment market sales revenue accounted for 56.6% of the global total, making it the largest industrial laser market in the world. China's rise to the top of the global industrial laser market relies not only on the resilience of its manufacturing clusters but also on the unwavering dedication of the first generation of "laser pioneers."

In the early 2000s, China’s industrial laser sector was almost a "technological desert." Foreign international giants monopolized the market with core technologies, laser prices were high, and critical components such as pump sources, specialty fibers, and fiber Bragg gratings were entirely imported. Domestic companies had little bargaining power and even struggled to secure stable supply. This "bottleneck" directly hindered the upgrade of Chinese manufacturing—many companies could not adopt advanced processing technologies due to the high cost of laser equipment.

The pain of this manufacturing bottleneck made "possessing an independent laser core" the urgent dream of a generation of laser engineers and laid the historical groundwork for the establishment of Chuangxin Laser.

In 2004, Chuangxin Laser emerged in response to this demand. As the first domestic professional fiber laser manufacturer, we did not take the shortcut of "assembly and low-end imitation" (which could bring quick profits at the time, but core technologies remained controlled by others). Instead, we strategically focused on "component-first." We knew that the performance stability and power accuracy of fiber lasers depended fundamentally on the quality of core components such as isolators, pump sources, and combiners. Only by achieving component independence could we truly break the monopoly. This clear understanding planted the first seed for the rise of domestically made fiber lasers in China.

In 2007, after successfully developing our own isolator, Chuangxin Laser officially embarked on the path of vertical integration of lasers and core components. However, breakthroughs in core technology were not easy—research and development required significant investment, long cycles, and had a high failure rate. Every tiny improvement in a parameter required hundreds or even thousands of experiments. Take the pump source as an example: as the "heart of the laser," it must maintain long-term stable output in high-temperature environments, and during development, even the heat dissipation structure had to undergo more than a thousand trials. Chuangxin Laser persevered with ten years of dedication, gradually overcoming these tough challenges.

Since 2012, Chuangxin Laser has successively mastered the key component technologies of pump sources, combiners, acousto-optic modulators, fiber Bragg gratings, laser output heads, and ultimately achieved 100% independent R&D of core components. This not only established a vertical integration model of "components-to-whole-machine," but also enhanced laser stability through the collaborative optimization of components and systems, while reducing production costs, laying the core foundation for subsequent domestic adoption.

This not only broke overseas technological monopolies and import dependence but also pioneered the model of vertical integration of lasers and core components in China, providing a reference path for domestic peers and solidifying the foundation for stable performance and cost control of domestic lasers.

Breaking overseas monopolies was just the starting point for Chuangxin Laser. Its unchanging ultimate pursuit is to build an even stronger "China Core" based on vertical integration and to promote the upgrade of the entire industry.

In 2019, the successful development of the 10kW energy combiner and the 10kW-level LOE laser output head marked a new milestone for Chuangxin Laser in core technologies. The breakthrough of the 10kW energy combiner allowed domestic 10kW lasers to double their power while maintaining beam quality, and the innovative design of the 10kW-level LOE laser output head enabled long-term stable output at the 10kW level. These two core technological breakthroughs completely broke the technological blockade held by overseas giants in high-power lasers, enabling domestic 10kW lasers to compete on the international stage with top brands.

In 2020, Chuangxin Laser further extended its vertical integration strategy upstream along the industry chain. The optical fiber research and production equipment platform established by its Wuhan Research Institute achieved full-chain self-controllability from core materials to devices and complete machines.

In 2021, Chuangxin Laser officially introduced its self-developed triple-clad high-power specialty fiber into the 10kW series of lasers. The triple-clad high-power specialty fiber, through innovations in materials and waveguide structure, comprehensively addressed three major challenges: thermal management, efficiency, and nonlinear effects. This systematic solution to the physical bottlenecks of high-power fiber lasers removed the main physical obstacles for the development of high-power lasers in China, laying a solid technical foundation for the development of ultra-high-power lasers in China.

In 2023, the launch of the 4200W large pump represented another self-surpassing advancement in core device technology. The 4200W large pump fully demonstrates Chuangxin's leading technology advantage of 'device integration,' incorporating three key technologies: integrated design (pump housing made of customized lightweight alloy material and molded as one piece, reducing weight by over 50%), triple-wavelength beam combining (using 915, 940, and 976 multi-wavelength combination technology for efficient coupling and maintaining electro-optical efficiency above 54%), and direct cooling (independently designed water channels integrating the pump and heat sink, achieving chip-level direct cooling—the industry's first realization of on-board chip cooling concept). These three technologies provide a stronger and more stable 'energy core' for lasers.

In 2024, the 160kW ultra-high-power energy combiner, LOE-M laser output head, and bus-type cutting head were successively developed and implemented, laying a solid technical foundation for the 160kW ultra-high-power multi-mode continuous industrial fiber laser and its applications to be recognized as 'Scientific and Technological Achievements.' This advancement has pushed domestic ultra-high-power laser technology to a new height, providing more reliable light source technology support for heavy manufacturing sectors such as new energy, automotive, shipbuilding, and aerospace.

This series of technological breakthroughs is not only a vivid reflection of Chuangxin Laser’s journey from having core devices to mastering them, but also highlights its strategic determination to cultivate the entire industry chain. Through a fully self-controlled 'materials-devices-complete machine' layout, Chuangxin Laser firmly grasps the 'lifeline' of industry development. Its success provides a clear reference for domestic peers—only by rooting in core technologies and deeply cultivating upstream and downstream of the industry chain can one break free from technological dependence and achieve true autonomy and self-reliance.

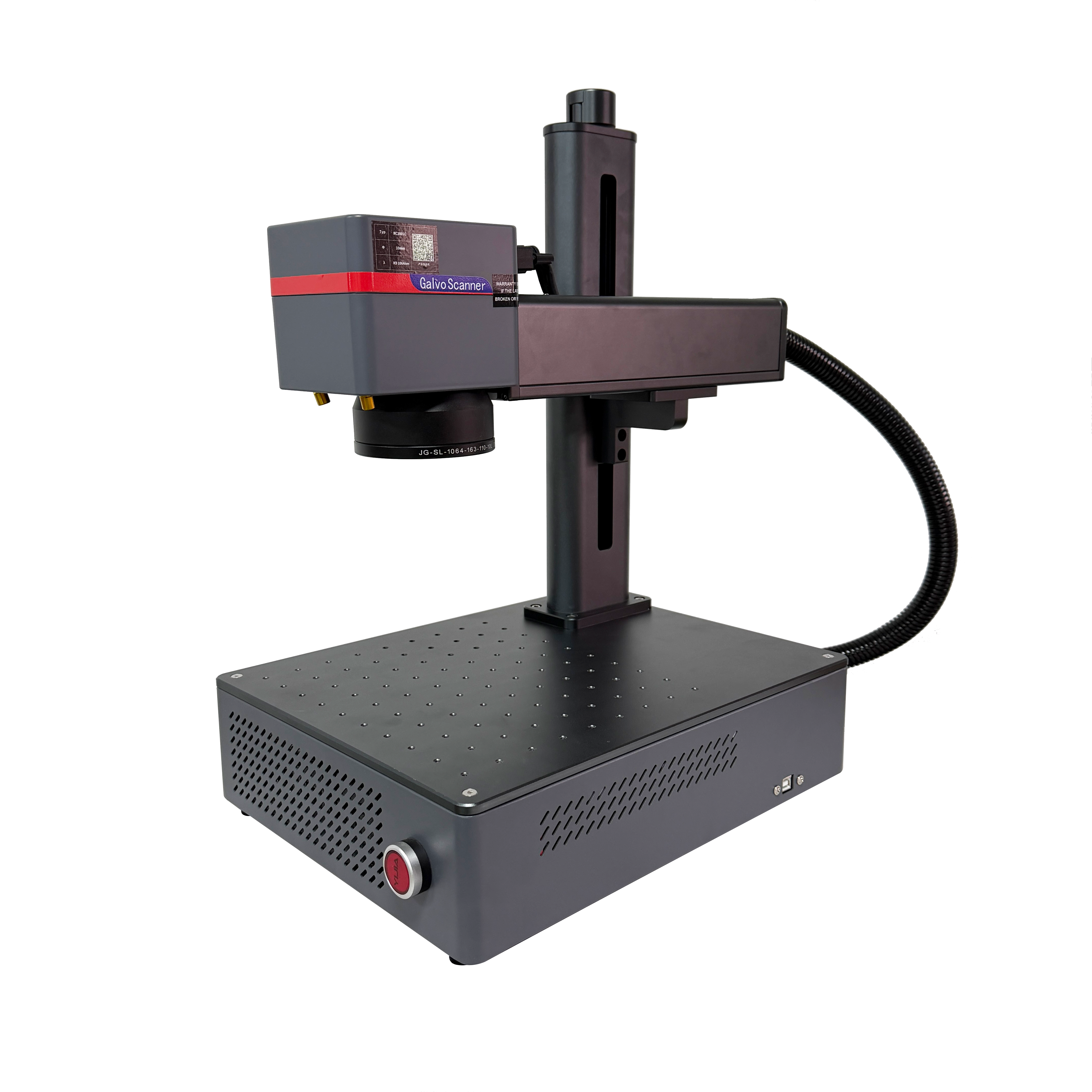

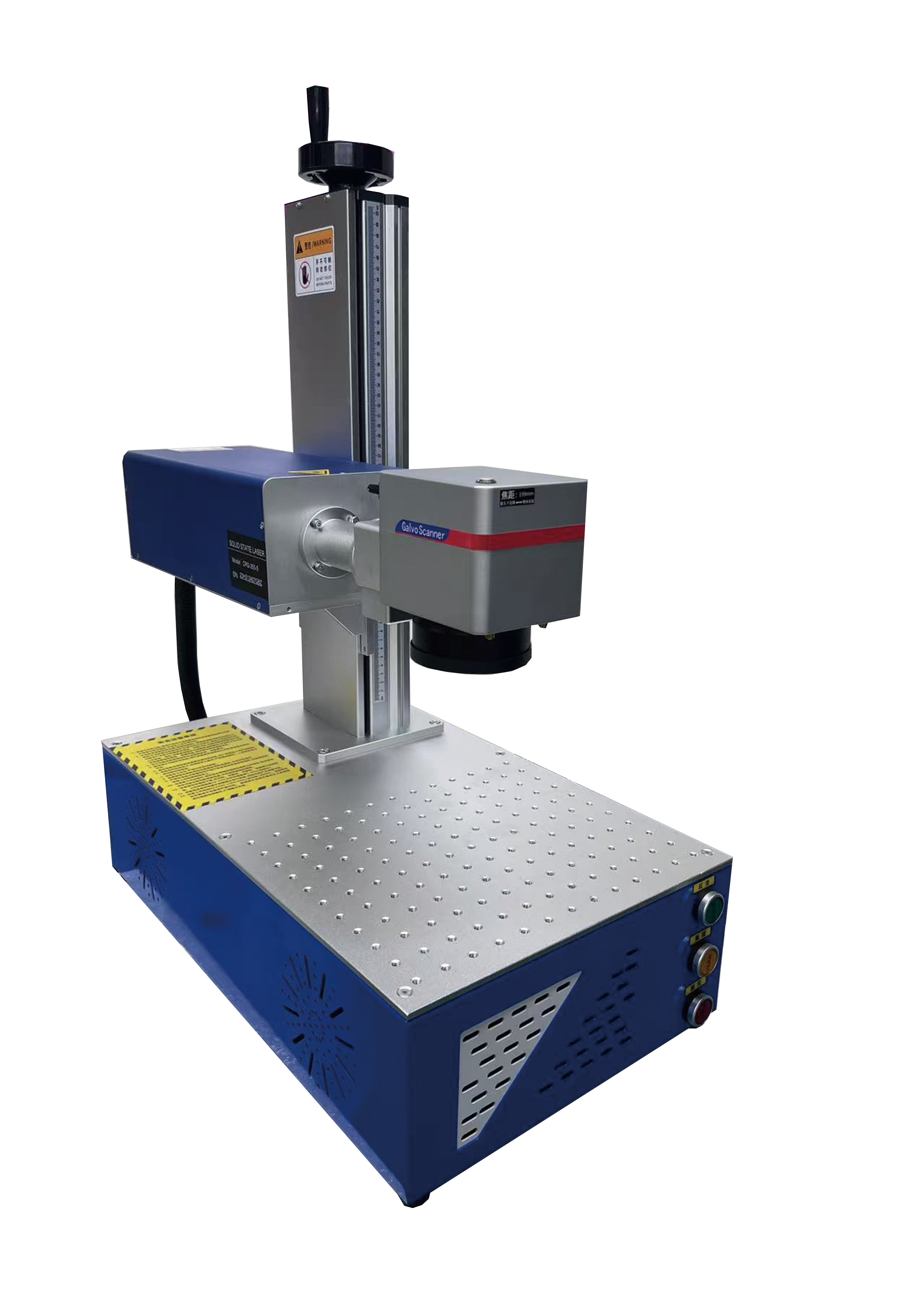

At the same time, the cost advantages and performance improvements brought about by technological breakthroughs have accelerated the adoption of domestically produced fiber lasers. Once regarded as high-end technology accessible only to a few large enterprises, laser technology has now entered countless small and medium-sized manufacturing factories, becoming an advanced tool for improving efficiency and quality across various industries, truly achieving the status of "becoming commonplace in everyday life."

As leading domestic laser manufacturers gradually implement integration strategies, the collective strength of China's laser industry has significantly increased, and the market share of domestically produced fiber lasers in China has steadily risen. According to statistical data, the localization rate of low- and medium-power fiber lasers has now reached 99%, almost completely reclaiming the market; the localization rate of medium- and high-power fiber lasers has also surpassed 75%, shifting from being a follower to a strong competitor.

This is not just a numerical leap but also an enhancement of China's influence in high-end manufacturing. From marking and cutting to welding, cleaning, and additive manufacturing... domestic lasers are reshaping China's—and even the global—manufacturing landscape with outstanding performance and accessible costs.

The story of Chinese lasers is written through countless moments of "daring to lead the industry," and we are still on the journey.

Post time: 01-21-2026