From budget to implementation!

Teach you how to choose the right industrial laser marking machine, doubling efficiency while keeping costs under control

Many procurement managers and technical supervisors often face a dilemma when choosing a laser marking machine: should they choose a fiber laser or a CO₂ laser? Is higher power always better? How can you balance performance with a limited budget? Don’t worry. As an industry-leading laser solutions provider, LAMBD has combined decades of industrial service experience to create a highly practical buying guide, helping you select the laser marking machine that best suits your own production, from needs assessment to equipment implementation.

The equipment meets the highest quality and technical standards and has a solid reputation in the industry.

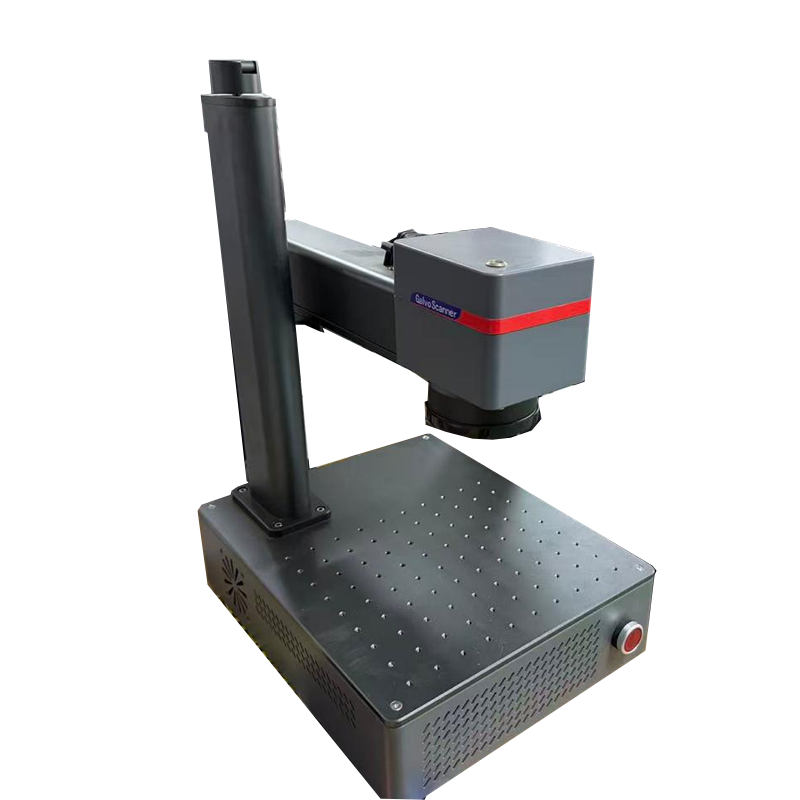

Advanced product lineup:

The models are suitable for industrial and professional scenarios, ensuring high-resolution marking results and equipment durability.

One-stop solution:

In addition to equipment, consulting and technical support are also provided to help enterprises efficiently implement laser marking processes.

Powerful versatility:

Supports continuous marking, meeting the needs of large-scale production without compromising precision, and covering both customized and batch production requirements.

02 Core Advantages of Laser Marking Machines You Must Know

Compared with traditional marking methods, laser marking has significant advantages:

Strong traceability: Can efficiently and accurately identify and track components in industrial production, making management easier;

Guaranteed quality: Marks are fade-resistant and damage-resistant, helping companies strictly control product quality;

High process efficiency: Fast speed and suitable for large-scale production lines, improving production pace;

Excellent durability: Marks can withstand industrial processing, water, and chemical corrosion;

Wide material compatibility: Can engrave a variety of materials, including metal, glass, plastic, and ceramics.

03 What factors affect the price?

The price of a laser marking machine is not fixed and is mainly determined by four factors:

Type of laser: Fiber lasers are suitable for metal and hard materials, offering high precision but at a higher price; CO₂ lasers are suitable for organic and non-metal materials, with a moderate price; MOPA lasers can handle both metals and some sensitive materials, and with advanced technologies like adjustable pulses and dynamic focusing, they can perform 3D marking, deep marking, and other multifunctional applications. Costs vary slightly depending on configuration (such as whether it includes autofocus or a 3D module), offering better value compared to traditional single-function machines;

Laser power: Measured in watts (W), the higher the power, the stronger the cutting and engraving capability, and the higher the price. Different models offer various power options;

Working area: The larger the area, the larger or more parts the machine can handle, and equipment price is usually higher;

Additional features: Machines with vision systems, automation modules, or the ability to integrate with production lines cost more, but can improve efficiency and precision.

04 Different Needs, How to Choose a Model?

Material Compatibility: For metals, choose a fiber laser machine or MOPA (especially for color marking or 3D marking); for wood, acrylic, and other organic materials, choose a CO₂ laser machine; for metals such as aluminum, copper, zinc alloy, titanium, and sensitive materials that require precise heat control, as well as scenarios requiring stainless steel color marking, MOPA is preferred.

Company Size and Budget: Small businesses or those with a limited budget can choose economical and practical diode equipment (suitable for non-industrial workloads); for industrial-level, high-output production, fiber laser machines are preferred for their reliability.

Special Requirements: If non-contact engraving is needed (to avoid material damage), customized marking (logos, serial numbers, etc.), or integration into an automated production line, the corresponding model can be selected based on the specific needs.

7 Key Points to Consider When Choosing

1. Clarify your own needs: Determine the materials to be marked, daily workload, and marking requirements (depth, precision, speed).

2. Choose the right laser power and type: Ensure the power meets the material processing requirements and the type is suitable for the material.

3. Consider installation space: Reserve space for the equipment and accessories (such as an exhaust system).

4. Pay attention to connectivity and ease of use: Prioritize devices that support Wi-Fi, USB, and other connection methods for easy integration.

5. Value technical support and training: Choose brands that provide reliable after-sales support and operational training.

6. Choose a trustworthy supplier: Opt for brands with a good reputation that offer warranty and personalized advice.

7. Select additional features as needed: Decide whether automation, vision systems, and other features are necessary based on production needs.

Post time: 12-26-2025