In-depth evaluation of laser marking machine manufacturers: industry preferred decision-making analysis and pit avoidance guide

"There are a wide variety of options on the market, but high-value decisions often stem from accurate insights into standards and reputation."

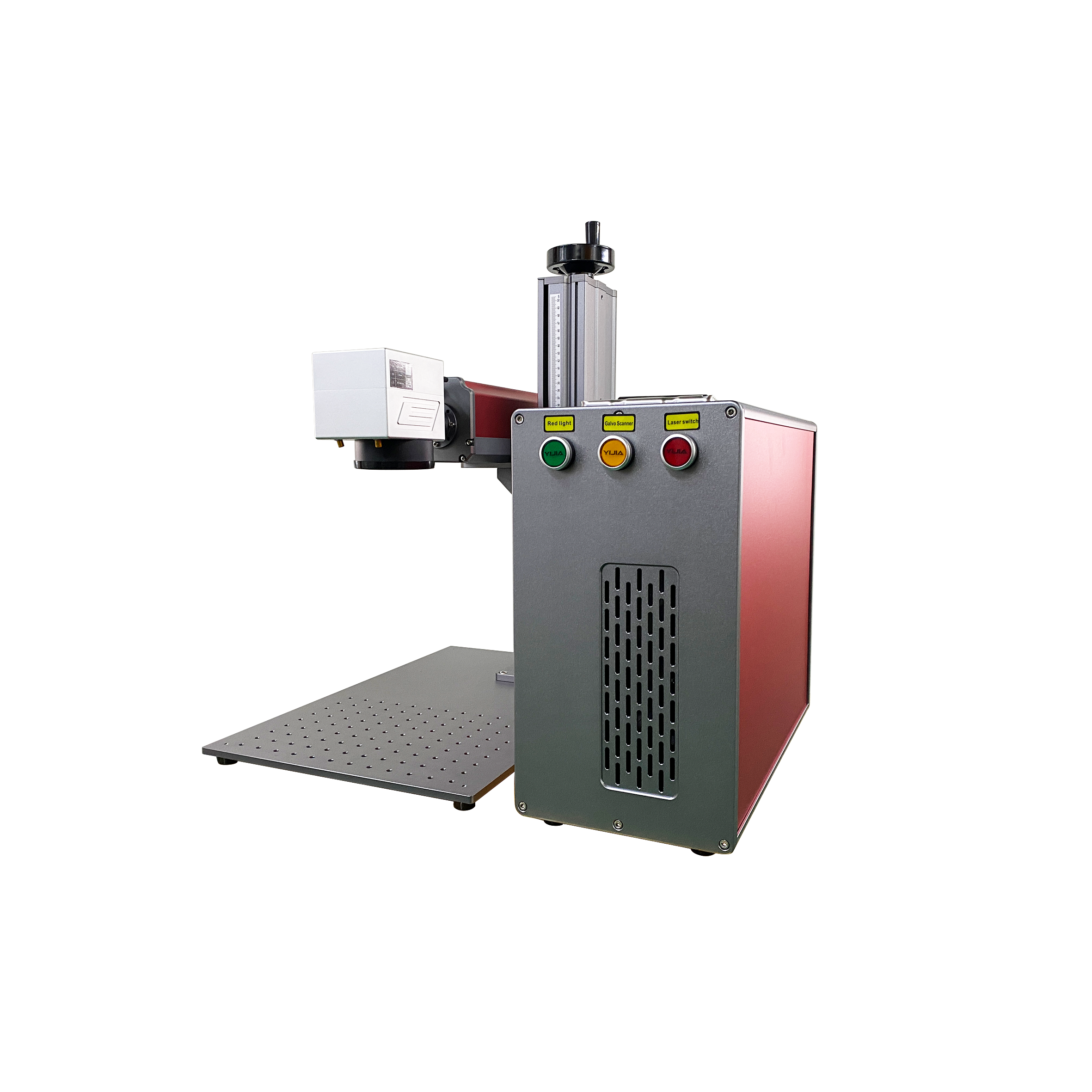

When you stand in front of the dazzling market of laser marking machines (laser engraving machines, laser laser machines), do you feel a little confused? From the seemingly similar parameters in the product catalog to the promised service, how to clear the fog and find a reliable and professional long-term partner for your production line? This is not only an equipment purchase, but also a strategic choice related to production efficiency, quality control stability and long-term operating costs. As a veteran laser marking machine company that has been deeply involved in the industry for many years, we deeply understand the deep anxiety and needs of every purchasing decision-maker - whether it is a business owner, engineer or procurement personnel - when faced with the core question of "how to choose a laser marking machine manufacturer".

Reconstruction of evaluation dimensions: Deep considerations beyond parameter tables

Choosing a laser marking machine (laser laser engraving machine) is much more than comparing power, speed and price. The true "evaluation" should go deep into the comprehensive evaluation of product performance, solution adaptation, service response and long-term value.

1. The "stability" of core performance: invisible quality is more critical

High stability means that the equipment can maintain the preset marking accuracy and speed under continuous operation and different working conditions, behind which is the comprehensive strength of core optical component quality, precision mechanical structure design and heat dissipation system. For example, when developing each model, our team will conduct "extreme working condition tests" on core lasers, galvanometers and optical lenses beyond conventional standards, simulating scenarios such as long periods of time, high load, and dusty environments to ensure that each hardware combination can withstand the test of "time war".

The business owner bluntly said: "The efficiency improvement brought by stability is the real cost performance." "This is precisely the dimension that many companies need to consider when looking for laser marking machine manufacturer recommendations.

2. The "professionalism" of scheme adaptation: non-standard customization capabilities are hard currency

Standard machines solve general problems, but in the actual production line, different sizes of workpieces, mixed materials, production line connections, space restrictions, etc. are the norm. A professional manufacturer, its core technical reserves are reflected in the ability to quickly design feasible non-standard laser marking machine customization or automation integration solutions according to the workpiece samples, production line layout sketches, and efficiency goals provided by customers. This requires manufacturers to have a solid comprehensive ability of mechanical design, electrical control, optical design and application process library.

3. The "timeliness" of service response: far more than the promised "warranty"

Quality service is a complete closed loop, from the frankness of pre-sales program evaluation, to the meticulousness of installation and commissioning in sales, to the rapid and active handling of after-sales problems. The key is, can remote technical support be available within a few hours when the equipment is in an unexpected condition? Can you get a wearable part at a reasonable cost? Buyers are often worried that "it is not easy to do after-sales if they are far away". In fact, it is not the straight-line distance on the map that determines the response speed, but the service system and engineer network of a brand. With a remote diagnostic system and standardized troubleshooting manuals, most problems can be resolved online. This kind of laser marking machine company recommendation with good after-sales service is based on the rapid response to the real pain points of customers.

From "price comparison" to "evaluation value": the upgrading of procurement thinking

Faced with complex market choices, it is recommended that decision-makers shift their thinking from pure "equipment acquisition cost" to "full life cycle cost of ownership" assessment. This includes:

Decision-making basis: Clarify your own needs (materials, accuracy, speed, production line integration, traceability requirements), and look for manufacturers who can clearly respond to your needs and give professional advice, rather than passively accepting "sales". For example, for manufacturers who need precision marking and are good at fiber laser marking machines, it is recommended to be the focus of inspection, while for non-metallic materials such as wood, plastics, etc., CO2 laser marking machines are a better choice.

Value assessment: Factors such as long-term trouble-free operation time brought about by equipment stability, improved product yield due to accuracy maintenance, and reduced maintenance downtime due to after-sales service efficiency are converted into hidden contributions to production efficiency and quality costs.

Trust Construction: Choose manufacturers that dare to demonstrate real application cases, production processes, and arrange for inspection of their production and commissioning capabilities. Word of mouth, especially real testimonials from customers in the same industry, is often more convincing than any flashy brochure.

We understand that every equipment choice carries customers' expectations for production upgrades and quality breakthroughs. Our persistence is not to achieve the ultimate parameters, but to ensure stability, reliability, adaptability and timely response throughout the whole process of each equipment from design to delivery to long-term service. We hope to become an "unknown, but indispensable" reliable node on the customer's production line, and support every trustworthy trademark and QR code with professionalism and responsibility.

A truly good device is one that makes you almost forget it exists – except for its consistent output.

Post time: 02-04-2026