Visual Laser Marking Machine: In-Depth Analysis of Technology and Applications

In the fields of industrial manufacturing and product processing, the development of marking technology has always been closely linked to production efficiency and product quality. The 'visual laser marking machine,' as a marking device that has gained significant attention in recent years, has gradually become an important choice for many companies to enhance their production capabilities.

PART 01What is a visual laser marking machine

A visual laser marking machine is a labeling device that integrates laser technology with visual positioning technology. In terms of precision, it can create clear and accurate marks on the surfaces of various materials, accurately displaying even tiny patterns or text, meeting the strict requirements of product labeling details.

PART 02Core advantage

For products of different specifications and shapes, traditional marking machines require frequent adjustments of fixtures or manual alignment, which is time-consuming and labor-intensive. In contrast, visual laser marking machines, with their built-in visual positioning system, are like equipping the device with 'eyes,' enabling it to actively recognize the position and outline of the products.

Smart positioning, accurate and efficient:Traditional marking machines often require manual positioning and calibration of products, which is time-consuming and prone to errors. In contrast, vision laser marking machines, equipped with built-in vision cameras, can quickly recognize the contours and positions of products, automatically complete positioning, and carry out marking.

The marking performance is stable and durable:Laser marking uses the energy of a laser to create permanent marks on the surface of materials. These marks will not fade or blur due to environmental factors such as friction, moisture, or high temperatures. Compared to traditional marking methods like ink printing, there is no need to worry about consumable usage or the marks falling off.

Easy to operate and highly adaptable:The equipment is equipped with a user-friendly interface, allowing staff to operate it proficiently after simple training, without the need for a professional technical background.

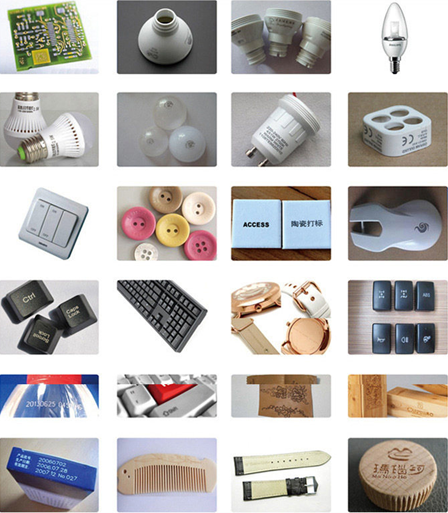

PART 03Application Scenarios

Electronic components industry: Visual laser marking machines play an important role. Electronic components such as chips, resistors, and capacitors are small in size and require extremely high precision for markings. They can accurately mark model numbers, parameters, production dates, and other information on the surface of these tiny components without affecting their performance.

Packaging and labeling industry: For products such as food, beverages, and cosmetics, consumers are increasingly concerned about information such as production dates, shelf life, and anti-counterfeiting details. It can quickly mark various packaging materials, whether plastic bottles, glass bottles, cartons, or metal cans, achieving clear labeling.

In the hardware industry: visual laser marking machines also demonstrate significant advantages. They can precisely mark brand logos, specifications, models, anti-counterfeiting codes, and other information on the surface of hardware products, with marking effects that are durable and not easily worn off due to long-term use or external friction.

The core difference between a visual laser marking machine and a traditional laser marking machine essentially lies in 'whether it has automatic positioning capability,' which can be specifically reflected in five dimensions: positioning method, applicable workpieces, labor costs, marking accuracy, and equipment cost.

1. Different positioning methods

The visual laser marking machine is equipped with an industrial camera and visual analysis software, capable of automatically capturing images of workpieces, comparing them with standard templates, calculating positional deviations, and correcting the marking path in real time, without any human intervention. In contrast, traditional laser marking machines rely on manual adjustment of the workpiece position or precise tooling fixtures to fix the workpiece, and it is essential to ensure that the workpiece is perfectly aligned with the preset marking position; otherwise, marking misalignment may occur.

2. Suitable for different workpieces

Visual laser marking machines are better suited for workpieces with 'no fixed placement posture,' such as small electronic components or parts produced in mixed-batch lines. They can accurately mark even if the workpieces are slightly tilted or shifted. Traditional laser marking machines are more suitable for workpieces that 'require a fixed placement posture,' such as larger parts produced in single-batch quantities, and they demand higher consistency in workpiece placement.

3. Different labor costs

The visual laser marking machine does not require a dedicated person to align the workpiece and can achieve unmanned batch processing, significantly reducing labor input and lowering long-term labor costs. Traditional laser marking machines require manual assistance to adjust the position of the workpiece, especially in scenarios with small batches and multiple models, where the frequency of manual operations is high and labor costs are relatively higher.

4. Different labeling accuracy

The positioning accuracy of a visual laser marking machine is higher, typically reaching ±0.01mm. Its precision is determined by the hardware and algorithms of the vision system, offering strong stability and capable of meeting high-precision marking requirements for chips, medical devices, and other applications. Traditional laser marking machines have medium accuracy, generally around ±0.05mm, with precision affected by the operator's skill or the accuracy of the fixture, resulting in relatively lower stability.

5. Different equipment costs

The visual laser marking machine has a higher overall equipment purchase cost due to the addition of core components such as industrial cameras and visual software. Traditional laser marking machines lack a vision module, with the core configuration only including basic components such as the laser source and galvanometer, resulting in a lower initial equipment purchase cost.

Post time: 10-31-2025